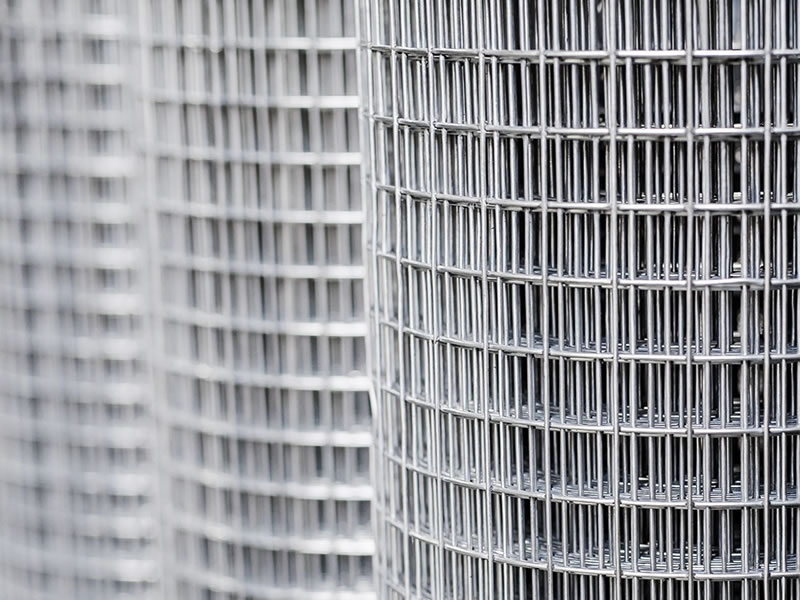

Welded wire mesh, characterized by its sturdy, consistent configuration, is crafted by welding steel wires at their junctures. This mesh is widely adopted in the construction sector for tasks such as reinforcement, fencing, and creating secure enclosures, thanks to its blend of robustness, security, and straightforward installation process. The stainless steel variant, in particular, is celebrated for its exceptional durability and ability to withstand environments prone to corrosive elements without the necessity for extra protective measures like galvanizing or PVC coatings. Available in various specifications, it also accommodates custom fabrication for specific gauge thicknesses and mesh dimensions, albeit with potential minimum order or setup requirements.

Material Variations for Welded Wire Mesh

Stainless Steel Options:

- Grade 304: A commonly used material due to its excellent corrosion resistance, adaptability to various environments, and overall durability. Ideal for general applications where exposure to corrosive elements is moderate.

- Grade 316: Known for its superior corrosion resistance, especially against chlorides and marine environments, thanks to the addition of molybdenum. Recommended for use in more challenging or chemically aggressive conditions.

Low Carbon Variants:

- Grade 304L: This variant maintains the properties of Grade 304 but with enhanced weldability and reduced risk of corrosion around welded areas. It’s preferred for projects requiring extensive welding.

- Grade 316L: Offers all the benefits of Grade 316 with added low carbon content, which further improves resistance to corrosion in welded parts. This variant is especially suited for harsh environmental conditions, making it ideal for marine and industrial applications requiring high durability and resistance to corrosion.

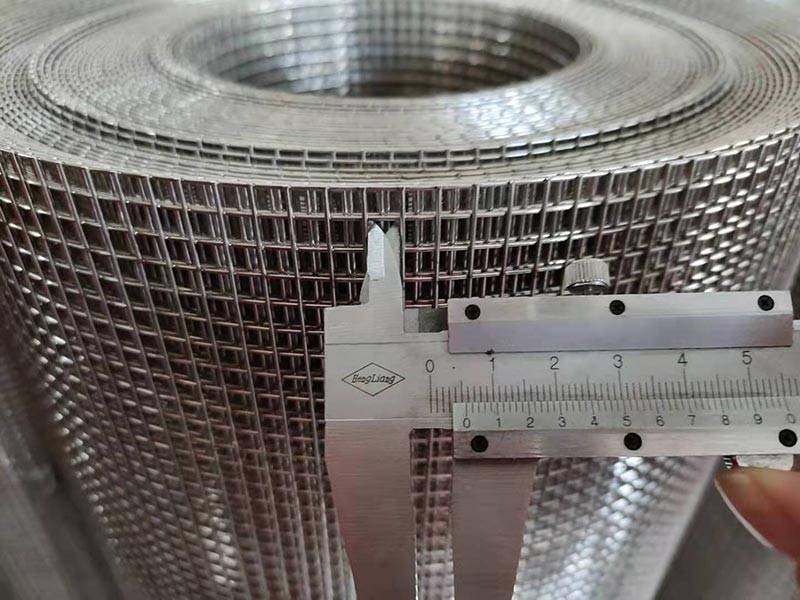

Stainless Steel Welded Wire Mesh Roll Specifications

| Mesh | Open Area | Wire Diameter | ||

| inch | mm | Max(mm) | Min(mm) | |

| 4″ | 4 | 101.6 | 8 | 2 |

| 3″ | 3 | 76.2 | 6 | 2 |

| 2″ | 2 | 50.8 | 6 | 1 |

| 1X2″ | 1X2 | 25.4X50.8 | 4 | 1 |

| 1″ | 1 | 25.4 | 3 | 1 |

| ¾” | 0.75 | 19.05 | 2 | 0.8 |

| 5/8″ | 0.62 | 15.8 | 2 | 0.8 |

| ½” | 0.5 | 12.7 | 2 | 0.8 |

| 3/8″ | 0.37 | 9.52 | 1.3 | 0.6 |

| ¼” | 0.25 | 6.35 | 1.2 | 0.5 |

Wire Diameter Specifications

Fine Diameter Range:

- Ultra-Fine Wires: Spanning from 0.025mm to 0.1mm, these are perfect for ultra-precision applications like micro-filtration.

- Fine Wires: This category includes diameters from 0.1mm to 0.5mm, making it suitable for precision tasks including fine mesh screens and detailed filtration processes.

Medium Diameter Range:

- Light Applications: Wires in the diameter range of 0.5mm to 1.5mm are adaptable for light applications such as residential fencing, indoor guards, and decorative uses.

- General Purpose: Diameters from 1.5mm to 3mm fall into this category, fitting a broad spectrum of applications including commercial fencing, machine guards, and medium-duty shelving.

Heavy Duty Diameter Range:

- Industrial Applications: With diameters stretching from 3mm to 5mm, these wires are engineered for reinforced structures, heavy-duty screens, and barriers requiring substantial strength.

- Maximum Strength: Diameters from 5mm to 8mm are reserved for the most demanding industrial applications, including structural reinforcement, security fencing, and heavy-load bearing screens.

Mesh Size Variations

Stainless steel welded wire mesh offers a wide array of mesh sizes to suit different needs, from tiny openings ideal for precise filtration to larger spaces designed for structural purposes. This range ensures versatility across various applications, from protective barriers to decorative elements.

- Fine Filtration Mesh: Ranging from 0.5×0.5mm to 1x1mm, these mesh sizes are designed for detailed filtration and delicate tasks requiring high accuracy.

- General Purpose Mesh: Sizes such as 25x25mm, 50x50mm, and 100x100mm cater to a broad spectrum of uses, including architectural features, machine protection, and agricultural enclosures.

- Structural Support Mesh: Extending up to 200x200mm, this category is aimed at construction needs, offering structural support, robust security fencing, and heavy-duty barriers for both industrial and commercial projects.

Processing Process

- Material Selection: This initial phase is about picking the appropriate steel, stainless steel, or other metals that match the specific requirements and environmental factors of the intended application for the mesh.

- Wire Drawing: During this stage, wire is meticulously thinned to its precise required diameter through dies, which prepares it for its ultimate purpose, whether for light or heavy-duty applications.

- Wire Straightening and Cutting: Utilizing precise machinery, wires are aligned and trimmed to exact lengths, a crucial step for the consistency and precision of the final mesh product.

- Crimping (Optional): This process, applied to certain designs, involves pre-crimping wires to infuse the mesh with specific textures or designs, enhancing both its aesthetic appeal and functional utility.

- Welding: The core of the process, welding involves securely joining wires at each intersection on a grid, using advanced welding techniques to ensure a sturdy, unified structure.

- Inspection and Quality Control: To guarantee the mesh meets high-quality standards, each panel is thoroughly inspected for consistent wire spacing, weld integrity, and overall structural robustness.

- Finishing: Post-inspection, meshes might undergo additional treatments like galvanizing or powder coating, enhancing their resistance to corrosion and wear while adding aesthetic value.

- Cutting and Shaping: Panels are then tailored to the exact dimensions required by customers, ensuring versatility across a multitude of applications.

- Packaging and Shipping: The final step ensures the mesh is securely packaged and transported, maintaining its condition until it reaches its installation site, ready for immediate use.