YuHeRen Wire Mesh Products Co., Ltd specializes in the production and distribution of Titanium woven wire mesh, catering to a broad spectrum of needs with an extensive range of types and specifications. Our Titanium woven wire mesh is celebrated for its superior corrosion resistance, lightweight properties, and non-toxic nature, making it an ideal choice for various applications. The unique ability of our high-purity titanium mesh to form a protective oxidation film in corrosive environments shields the mesh from degradation, ensuring its longevity and durability. Excelling in challenging conditions such as exposure to seawater, chlorinated solutions, nitric and chromic acids, as well as metal chlorides and organic salts, our titanium mesh stands as a preferred alternative to traditional materials like nickel-free stainless steel and aluminum wire mesh.

Specifications and Customization

Material Options: Our Titanium Woven Wire Mesh is available in two primary grades, catering to various application needs. Titanium Grade 1 (TA1, UNS R50250) offers exceptional ductility and corrosion resistance, making it suitable for applications requiring high formability. Titanium Grade 2 (TA2, UNS R50400) provides a balanced combination of moderate strength and corrosion resistance, ideal for a broader range of uses.

Wire Diameter: The thickness of our titanium wires can vary significantly, providing the flexibility to customize the mesh for different strength and permeability needs. Precise adjustments to the wire diameter can be made to match the specifications of your project.

Aperture Size: Titanium Woven Wire Mesh is available with aperture sizes ranging from as small as 0.02mm to as large as 23.7mm.

Mesh Count: Offering a broad spectrum from 0.3 mesh up to 400 mesh, our Titanium Woven Wire Mesh caters to both coarse and fine filtration needs.

Width Options: With widths available from 5mm to 2000mm, our Titanium Woven Wire Mesh can accommodate projects of any scale.

Packing and Delivery: To ensure the highest level of protection during transportation, our Titanium Woven Wire Mesh is meticulously packed using a waterproof bubble pad and waterproof paper, all secured within a sturdy wooden box. This comprehensive packaging solution guarantees that your order arrives in perfect condition, ready for implementation in your project.

Weaving Techniques:

Titanium woven wire mesh is available in four specialized weaving techniques, each designed for distinct uses and outcomes.

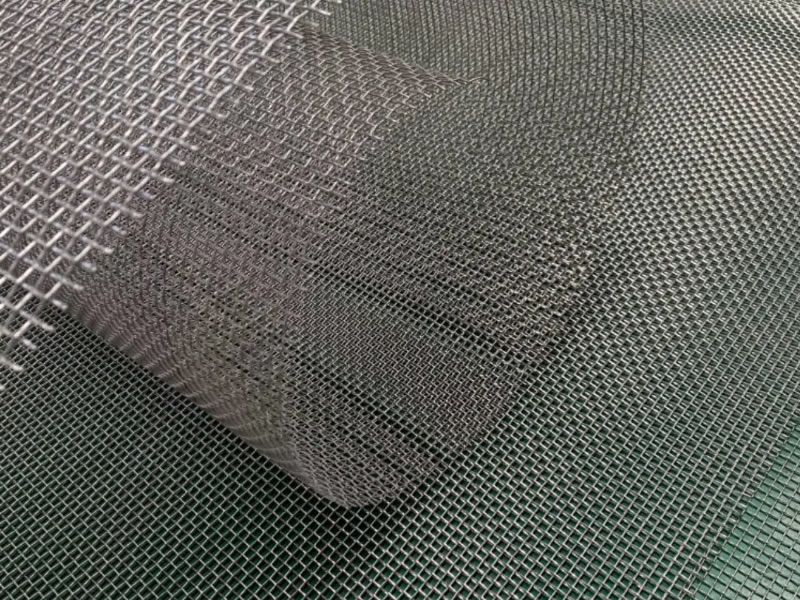

- Plain Weave: This basic approach weaves weft and warp wires of the same diameter in an alternating over-and-under pattern, yielding a consistent and snug mesh ideal for various precision-based applications.

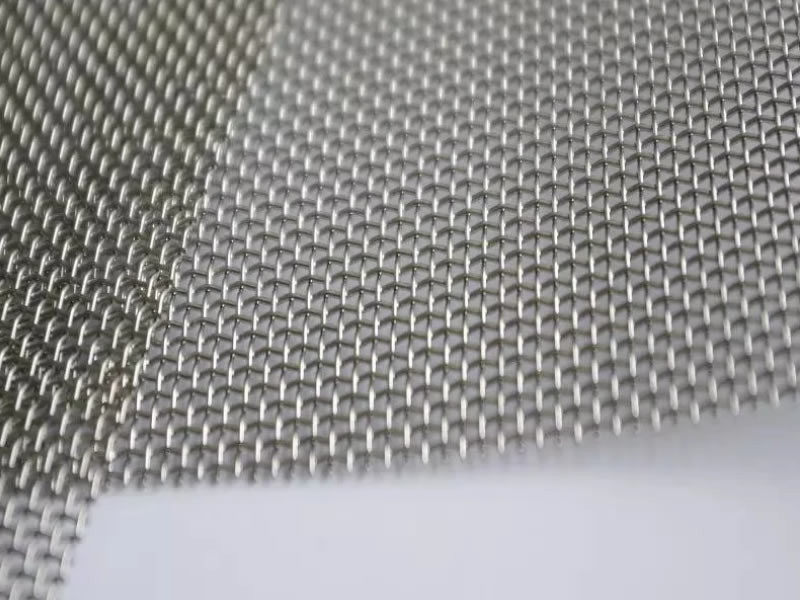

- Twilled Weave: Designed for use with heavier gauge wires, twilled weave crosses warp and shute wires in pairs, resulting in a thicker, more robust mesh suitable for high-strength and enhanced filtration needs.

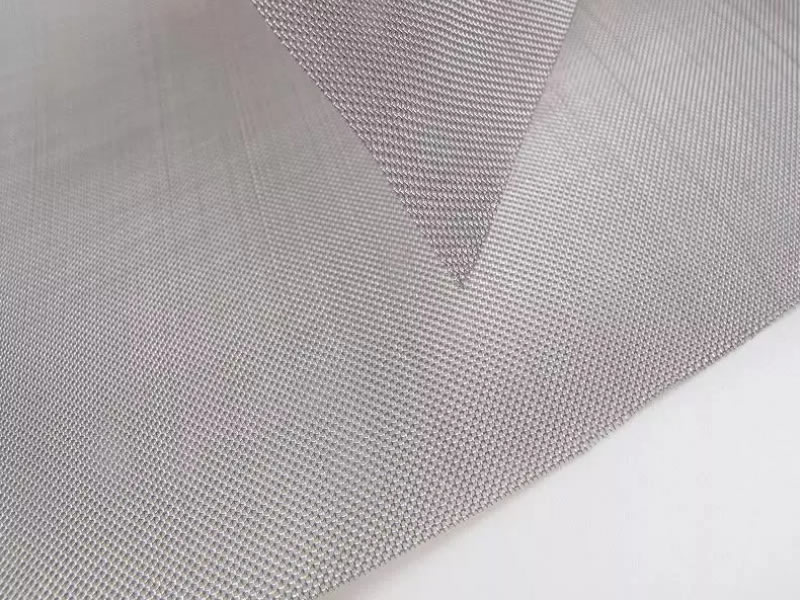

- Plain Dutch Weave: Utilizing larger warp wires compared to shute wires, this technique forms a compact, wedge-shaped mesh, perfect for fine filtration tasks requiring detailed separation.

- Twilled Dutch Weave: Merging the principles of twilled and plain Dutch weaves, this complex pattern features larger warp wires in a twilled configuration, achieving superior filtration efficiency and strength for complex industrial challenges.

These weaving techniques form the basis for customizing Titanium woven wire mesh to meet precise project specifications. Offering flexibility in design through a range of weaving styles and the ability to adjust wire diameters and mesh counts, we provide bespoke solutions tailored to the unique requirements of our clients.